Kingwhale’s Circular Economy - ReVioTM

Focusing on a circular system in textiles, Kingwhale is innovating the future of recyclable fibres. Using post-industrial, post-consumer discarded garments or fabric waste as the feedstock that would otherwise go to a landfill or incinerated, to regenerate them into new, eco-friendly materials. This regenerated material, ReVioTM , is meant to be resourceful to reduces the carbon emission, minimize environmental impact, regenerate and maximize the end-of-life use of textiles and garments.

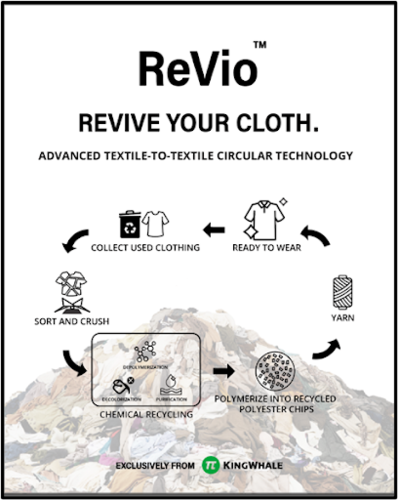

Reusing or upcycling textile products as much as possible is important. However, at end-of-life, products are landfilled or incinerated, releasing carbon into atmosphere, and contributing to global warming. In its effort of reducing carbon footprint, Kingwhale is transforming into a circular economy business operation. Investing into fully chemical recycling method to produce recycled PET chips. The ReVioTM technology process is 1.) collect those post-consumer and post-industrial wastes, 2.) sorting and pre-treatment, 3.) regenerate PET chips by fully chemical process - decolorization, depolymerization and purification, and 4.) apply recycled chips to produce yarn, fabric and garment. ReVio™ yarn performs as great as virgin polyester.

Kingwhale is also developing a product portfolio which includes alternative to fossil-based fibres in the long run. The goal is to develop natural, renewable materials, a process that boasts optimized Co2 emissions. Primarily application with plant-based, agricultural waste, and food waste. Not only resolving environmental impact, but also find ways to create higher value from the residue of existing food, and as a result creating value which limiting the carbon footprint of farming.

“Taiwan imports more than 90% of its energy, fertilizers, and feeds and over 60% of its food. Thus, it is essential for Taiwan to increase resource efficiency and recycling by moving towards a circular economy. Kingwhale’s transition will benefit the environment and fulfil the needs for a global green supply chain. We aim to help brands respond to the market demand for more sustainable developed products. Also providing circular economy options to our customers, offering a holistic way to move towards a greener product portfolio”, said by James Huang, the CEO of Kingwhale.

The adoption of circular economy principles offers manufacturers significant business opportunities in areas ranging from sustainability, brand image and stakeholder value. Kingwhale will continuously dedicate to apply low impact and circular economy technologies into developing high performance fabrics and garments, aiming a goal to provide people a comfortable & valuable lifestyle and to protect human a green & sustainable environment.

Established in 1992, Kingwhale is a vertically integrated manufacturer with innovative material science, advanced production process and versatile design approaches that supply global clients with high performance products and integrated commercial services. Our products ranges from fibre spinning, knitting, dyeing, special finishing and GORE-TEX certified garment factories. It is an important strategic partner of major sports brands globally.

Watch the Kingwhale COP28 interview

Kingwhale has committed to sustainable operation. Kingwhale has join the RE 100 initiatives, the very first textile manufacturer in Asia Pacific, committed to 100% renewable energy by 2040.

Kingwhale’s company logo and philosophy: “π = 3.1415926…… a decimal representation that never ends, inspires our business philosophy. Although we know that pursuing absolute perfection is an unattainable and endless journey, we are not swayed in our determination to make every endeavor to achieve it. We have nothing to offer customers but our very best.”

Media Contact:

Saffron Dale

Acumen Media

Distribution Coordinator

s.dale@acumenmedia.com