PACE Steel Belt Systems Launches New Specialist Thermal Profiling and Internal Oven Camera Technology for Continuous Oven Monitoring

PACE Steel Belt Systems Launches New Specialist Thermal Profiling and Internal Oven Camera Technology for Continuous Oven Monitoring

PACE Steel Belt Systems, an industry leader in industrial conveyor and oven systems, is excited to announce its latest advancements in continuous oven monitoring technology. The company now offers specialist thermal profiling services and has developed an innovative internal oven camera system designed to capture high-quality video footage of all baking stages in real time.

PACE Steel Belt Systems is addressing the industry’s growing need for precise monitoring and control within continuous oven processes, such as those used in food, pharmaceuticals, and other sectors that rely on strict temperature regulation and consistent product quality. With this introduction, PACE enables manufacturers to achieve unprecedented insight and accuracy in their thermal processes, helping them enhance productivity and reduce waste.

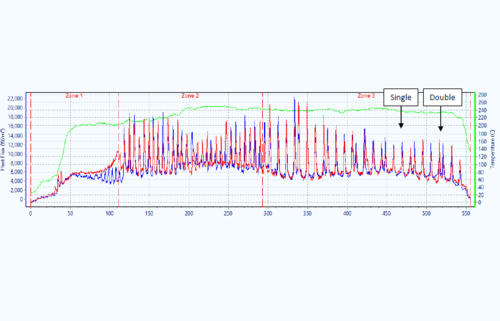

The newly introduced specialist thermal profiling service employs advanced sensors to capture detailed temperature data across all zones of the oven. By providing a comprehensive view of the oven’s thermal environment, the profiling service allows operators to detect variations in temperature that could impact product quality, leading to better process control and faster identification of potential issues. The service is tailored to meet the unique needs of each client, whether optimizing existing processes or validating new production setups.

Complementing the thermal profiling service, PACE is launching its cutting-edge internal oven camera system. This robust camera has been designed to withstand extreme oven environments and can be safely transported through the oven on the conveyor belt, capturing clear, high-resolution video of the product as it progresses through each stage of the baking process. This groundbreaking technology gives manufacturers the ability to visualize the entire baking or drying process, identify product inconsistencies, and gain deeper insight into how different stages impact final product quality.

“These innovations underscore our commitment to delivering cutting-edge solutions that empower our clients to achieve higher production quality and efficiency,” said Paul Lawson, Managing Director at PACE Steel Belt Systems. “By combining specialist thermal profiling and internal oven video technology, we’re equipping manufacturers with powerful tools to optimize their processes and address the challenges of modern production demands.”

PACE Steel Belt Systems continues to push the boundaries of process control technology, enabling companies to take advantage of a more data-driven and visual approach to production. The new thermal profiling and camera solutions are now available globally.

About PACE Steel Belt Systems

PACE Steel Belt Systems is a premier provider of steel belt conveyor systems and continuous ovens used in a variety of industries worldwide. Known for innovation and reliability, PACE has been pioneering process control solutions that help manufacturers optimize production and enhance product quality.

ENDS

For further information, please contact:

Paul Lawson – CEO

PACE Steel Belt Systems

Phone: 01384 898237

Email: P.Lawson@pace-berndorf.co.uk

Unit 2, College Farm, Six Ashes Rd, Bridgnorth WV15 6EL

www.pace-berndorf.co.uk

For media inquiries please contact sales@pace-berndorf.co.uk 01384 898237