New technique reveals 6,000-year-old manufacturing process

To uncover the secrets of a 6,000-year-old amulet, the oldest known lost-wax cast object, scientists have developed a novel imaging technique

PRESS RELEASE: FOR IMMEDIATE RELEASE

New technique reveals 6,000-year-old manufacturing process

To uncover the secrets of a 6,000-year-old amulet, the oldest known lost-wax cast object, scientists have developed a novel imaging technique that allows the manufacturing process to be reconstructed at a level of detail never achieved before.

Researchers from the IPANEMA laboratory (CNRS, MCC, UVSQ) and synchrotron SOLEIL at Université Paris-Saclay studied the amulet from Mehrgarh, Pakistan, using a new photoluminescence imaging approach. The full corrosion of the artefact made by lost-wax casting – a method used to duplicate metal sculptures cast from an original model – had, up to now, hampered the understanding of the metallurgical sequences used by metalworkers.

Through a wide-ranging collaboration project with scientists from C2RMF, Pré-Tech, ArScAn and TRACES laboratories, the team from IPANEMA revealed a hidden microstructure by shining light in the UV/visible range on the object, generated by a contrast of luminescence induced by variations of crystalline defects within the corroded amulet. Such ghost microstructure, invisible with other advanced techniques, reveals the full metallurgical sequence in the creation of the amulet and its degradation during burial.

Located on the SOLEIL synchrotron site at Université Paris-Saclay, IPANEMA is a laboratory dedicated to research and development of advanced methodology of materials’ characterization in archaeology, palaeo-environments, paleontology and cultural heritage research.

“Scientists had reached the limits of what they could learn from the amulet with traditional imaging techniques since its discovery three decades ago. We designed a full-field photoluminescence approach to look at the object’s structure and composition in greater detail,” says author Mathieu Thoury.

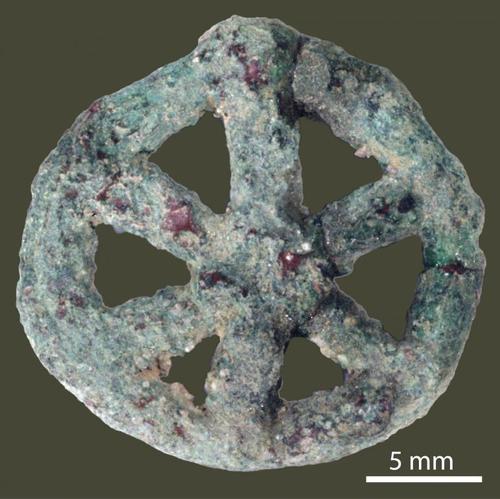

The ‘spoked wheel’ shape of six small rods on a ring of 20-mm diameter was confirmed to be cast in a single piece, without any soldered parts, and, surprisingly, metalworkers of Mehrgarh used very pure copper – indicating innovative development into metallurgy at the time. Using high-purity copper was soon rejected by the founders in Pakistan who discovered that adding lead increased the metal fluidity.

The research sheds light on the invention of high-precision foundry that is still used today. Lost-wax casting is a precise metal forming technique – also called ‘investment casting’ – in aerospace, aeronautics, and biomedicine, for high-performance alloys from steel to titanium.

“Although it has never been used in archeology, the photoluminescence imaging technique developed here holds great promise for this field and other disciplines, including environmental sciences and geophysics,” say authors Mathieu Thoury and Loïc Bertrand.

These findings were first published in the journal Nature Communications.

/END

The article is available in Open Access at: http://www.nature.com/articles/ncomms13356

For more information, or to speak with the researchers, please contact Stephanie Mullins at BlueSky PR – smullins@bluesky-pr.com or call +44 (0) 1582 790 706

This press release was distributed by ResponseSource Press Release Wire on behalf of BlueSky Education in the following categories: Leisure & Hobbies, Environment & Nature, Education & Human Resources, Manufacturing, Engineering & Energy, Construction & Property, for more information visit https://pressreleasewire.responsesource.com/about.