Domino Helps Customers Reduce Risk and Optimise Production With New Vision Inspection Systems

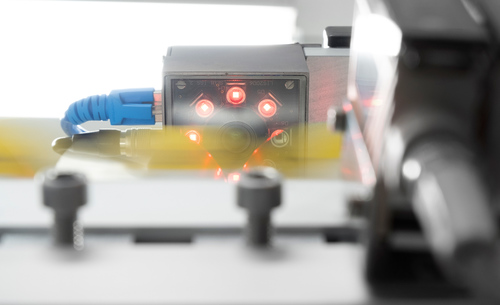

Domino Printing Sciences (Domino) is pleased to announce the launch of the R-Series, a new range of smart vision systems for automatic inspection and validation of product codes, including date codes, batch numbers, barcodes, and 2D-printed codes.

The R-Series was developed in consultation with customers following Domino’s acquisition of Lake Image Systems. Domino has long recognised the importance of code validation for manufacturers and realised the customer value in reducing complexity and offering a complete end-to-end solution from a single trusted partner.

Specifically designed to work with Domino printers and coders, the R-Series eliminates the need for manual code validation and inspection, significantly reducing the risk of an incorrect code leaving a manufacturing site unnoticed, while allowing for more efficient use and distribution of resources.

“Coding errors pose a significant financial risk to manufacturers – and this goes much further than the risk of manufacturing waste and need to rework incorrect stock,” says Andy Barrett, Portfolio and Requirements Director, Domino. “If left to enter the supply chain, an incorrect code can necessitate a product recall, which is not only costly in terms of logistics but can also damage the long-term value of a company.”

“With the R-Series, we can offer our customers a range of integrated vision systems that automate the checking of every code, so that unidentified coding errors become a thing of the past,” continues Barrett.

The launch highlights Domino’s ongoing commitment to ‘Do more’ to help customers improve production efficiency and reduce manufacturing waste by delivering ‘best-in-class’ customer experience through products, services, and expertise.

“The R-Series completes a closed-loop coding solution from Domino, also encompassing our trusted printing solutions and QuickDesign coding automation software,” says Craig Stobie, Global Sector Development Director, Domino. “By partnering with Domino to validate their coding and marking systems, our customers can protect their operations from coding errors, reduce the risk of manufacturing waste, and increase overall equipment effectiveness and product yields.”

R-Series systems have been developed to work alongside Domino printers, integrating seamlessly into existing production lines without the need for custom brackets or specialist add-ons. R-Series controllers can be run from a single human-machine interface and have a standard user interface with Domino ‘look and feel’, which is easy to learn and reduces the need for additional training.

Unlike other vision systems, the R-Series is specifically designed for coding and marking applications. The systems are optimised for Domino fonts, print characteristics, and inks and match the speed of Domino’s fastest printers, meaning that manufacturers can code with confidence, knowing that every code that is printed can be checked and verified.

The R-Series is available as three separate products, with bespoke options available to cater for all requirements and budgets. The top-level R550 is a complete code validation and verification solution, which validates the data for both human- and machine-readable codes, as well as checking for readability and code placement. The mid-range R350, checks the readability of machine-readable codes, while the R150, a cost-efficient introductory option, offers simplified checking for code presence and placement.

“We are incredibly proud to be able to offer our customers an industry-leading vision inspection product range in the Domino R-Series,” says Praba Sivalingam, Global Solutions and Support Director, Domino. “With this capability, Domino can satisfy customers’ coding and vision needs via a single reputable brand, while taking full responsibility for installation, training, and after-sales support, globally.”

To find out more about the R-Series, please click here.

Disclaimers

General

All performance related figures and claims quoted in this document were obtained under specific conditions and may only be replicated under similar conditions. For specific product details, you should contact your Domino Sales Advisor. This document does not form part of any terms and conditions between you and Domino.

Imagery

Images may include optional extras or upgrades. Print quality may differ depending on consumables, printer, substrates, and other factors. Images and photographs do not form any part of any terms and conditions between you and Domino.

Notes to Editors:

About Domino

Since 1978, Domino Printing Sciences (Domino) has established a global reputation for the development and manufacture of coding, marking, and printing technologies, as well as its worldwide aftermarket products and customer services. Today, Domino offers one of the most comprehensive portfolios of complete end-to-end coding solutions designed to satisfy the compliance and productivity requirements of manufacturers across many sectors, including food, beverage, pharmaceutical, and industrial. The company’s core technologies include innovative inkjet, laser, print and apply, and thermal transfer overprinting systems designed for the application of variable data, barcodes, and unique traceability codes onto product and packaging.

Domino employs over 2,900 people worldwide and sells to more than 120 countries through a global network of 25 subsidiary offices and more than 200 distributors. Domino’s manufacturing facilities are located in China, Germany, India, Sweden, Switzerland, UK, and the USA.

Domino’s continued growth is underpinned by an unrivalled commitment to product development. The company is the proud recipient of six Queen’s Awards in several categories, including innovation. Domino has also been recognised with many industry awards, including the ‘Supply Chain Excellence’ and ‘People and Skills’ accolades at The Manufacturer MX Awards 2019.

Domino became an autonomous division within Brother Industries Ltd. on 11th June 2015.

For further information on Domino, please visit www.domino-printing.com

Issued on behalf of Domino by Neo PR Limited.

For more information, please contact:

David Mieny

PR Account Director

Neo PR Limited

Tel: +44 (0) 1296 733 867

David@neopr.com

Jasmin Woodward

Marketing Campaigns Specialist

Domino Printing Sciences

Tel: +44 (0) 1954 782551

Jasmin.Woodward@domino-uk.com

Jade Taylor-Salazar

Written Content Specialist

Domino Printing Sciences

Tel: +44 (0) 1954 782551

Jade.Taylor-Salazar@domino-uk.com